“Subhub supports all the through life requirements of an array of tidal turbines. By self-deploying, in a single offshore operation, it saves cost, reduces operation risk and increases site yield.”

SUBHUB Tidal Platform

Subhub supports every stage of a tidal turbines life from integration ashore to deployment, installation and retrieval for maintenance and finally decommissioning.

What is Subhub Tidal Platform

Subhub is a submersible, gravity based, foundation platform that supports every need of tidal turbines through life.

- Its unique ballasting system enables it to be self installing and self aligning with the flow

- It requires limited amount of support from commonly available tugs and barges

- Therefore only requires a single, quick offshore operation to install it making deployment an extremely low cost exercise

- Importantly it has high availability of marine operations because it has wide weather, wave and tidal windows.

- The hull form is carefully designed to accelerate the flow to extract the most energy from the site and overcome tidal shear

- Significant environmental benefits of no-noise installaiton with zero aesthetic impact on the seascape

Benefits of Subhub

Low cost deployment using harbour tugs

Cheap to install and maintain

Enhances tidal site yield by up to 48%

Environmentally low impact on seascape and seabed and marine life

Through life support of tidal turbines

Integration Ashore

Full systems integration is conducted at the quayside. This is much safer and logistically easier than connecting up tidal turbine systems offshore. Most importantly it means the cost of deployment is substantially reduced since there is NO reliance put on large and specialist installation structures. Only harbour tugs and multicats are required which are commonly available and about 10x less expensive to anchor handlers and/or DP2 vessel and 15x less expensive to jack-ups and crane vessels.

Deployment

Subhub is a fully integrated platform. That means it has everything onboard that it requires through its life. Therefore it can be deployed in a single offshore operation with very little support required from vessels. In fact, commonly available harbour tugs is all that is required to deliver the Subhub tidal platform to the tidal site.

Subhub is designed to be towed offshore in high sea states and this has been proven in the deployment of the demonstrator in near gale and rough conditions during its transit from Belfast Harbour to Strangford Lough. Commercial pressures can force schedules and having large operating weather windows is important for maintaining deployment rates and costs.

Installation

The installation and retrieval stages of any tidal turbine is the riskiest part of any offshore operation and this is where Subhub excels. Instead of using a heavy lift crane barge or DP2 installation vessel, which are assets lent from the O&G industry, Subhub uses buoyancy and its excellent stability characteristics when submerged to dive to the seabed. QED Naval have proven this installation and retrieval in both model and full scale.

One of the key advantages of this installation method is its simplicity, reversibility and robustness against against environmental conditions. The model and demonstrator has been proven in a broad range of environmental conditions.

Retrieval for Maintenance

Retrieval for maintenance is as simple as installation and means maintenance costs can be minimised. All that is required is a generator (400V, 3 phase) to power the Hydraulic Power Units (HPU) and an air compressor to provide Low Pressure (LP) Air. The hydraulic systems control the seawater and air inlet valves and the LP air is used to displace the water within the Subhub’s numerous seawater ballast tanks.

Decommissioning or Re-Use

Decommissioning of the tidal field is a matter of retrieving the Subhub and towing it away along with all the rest of the electrical infrastructure contained onboard the platform. Once at the yard the platform can be assessed by Marine Warranty Survey’s and considered for refit and re-use or cut up and the steel sold as a commodity.

All the electrical and ballast system can be stripped out and serviced and re-used. The electrical and mechanical connectors are high grade stainless steel and have long service lives so they could be sold or re-used.

SUBHUB Versions

The design tools used to develop the demonstrator have been well validated so scaling up is easily done and well understood. In fact, the physical scaling laws governing the design means that scaling up provides significant benefits simplifying the manufacturing process and hence further reducing CAPEX costs.

Three different scales have been assessed by QED Naval.

Gen 01

Community Scale

Ideal for community power projects or cost effective low flow sites.

- Tidal turbine diameters from 4.0m – 8.0m

- Ideal water depths between 8.0m to 20.0m

- A peak power output of between 150kW – 300kW

- The platform is enough to power 89 homes

- Can directly offset up to 89t of CO2 per year

Gen 02

Industrial Scale

Ideal for industrial loads such as small distilleries or faster river flow sites.

- Tidal turbine diameters from 8.0m – 16.0m

- Ideal water depths between 16.0m to 32.0m

- A peak power output between 300kW – 1.25MW

- This platform is enough to power a small factory

- Can directly offset up to 447t of CO2 per year

Gen 03

Utility Scale

Best suited to large field deployments and deeper water with faster flows.

- Tidal turbine diameters from 16.0m – 24.0m

- Ideal water depths between 32.0m to 48.0m+

- A peak power output between 2MW<>4MW

- This platform is enough to power a small town

- Can directly offset up to 1064t of CO2 per year

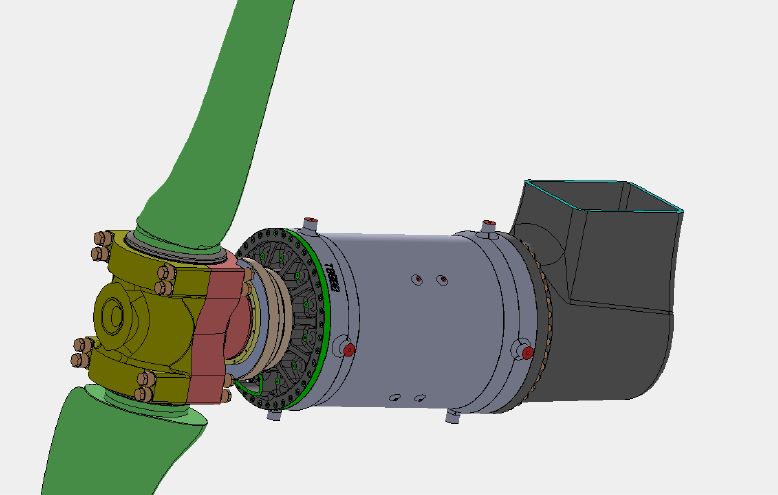

Tocardo Tidal Turbines

Subhub tidal platform can be designed around any type of tidal turbine. However, QED acquired one of the world's reknowned tidal turbine companies called Tocardo in a Joint Venture with Inyanga/HydroWing, a like minded marine operations and technology company. Tocardo brings innovative Dutch engineering that is characteristised by efficient, reliable and really robust technology. Their tidal turbines have been operated in the Dutch storm barriers and sluice gates for over decade.

T-01

Community Scale (50 – 100kW)

The T-1 is Tocardo’s most proven turbine. By generating energy in a predictable and cost effective way the T-01 is the best tidal turbine in its market segment with power outputs ranging from 50 to 100 kW. Due to its relatively small size it can be installed in shallow waters (4 meters and deeper). The turbines are made to last with very minimal maintenance. The design lifetime is at least 20 years.

The Subhub Community Demonstrator is design around a 4.0m diameter Tocardo T1 tidal turbine. These are arguably the most robust, reliable and well proven tidal turbines in the world having had over a decades worth of operation and development in Den Oever, Holland, shown below.

T-02

Industrial Scale (120 – 250kW)

Tocardo T-2 tidal turbines offer a step up in power generation capabilities on a commercial basis which benefit more industrial applications or deployed as an array. By generating energy in a predictable and cost effective way the T-2 is a medium sized tidal turbine suitable for various locations, with power outputs ranging from 100 kW to 250 KW.

T-03 & T-04

Utility Scale (200kw to 1MW+)

The T-3 is a medium sized tidal turbine capable of up to 450 kW output.

Cost-effectiveness is critical to making the business case viable and to convince decision makers that tidal energy solutions are a good investment. This goal will be achieved by the development of the Tocardo T-3 turbine series. The improved transition piece allow the turbine to be installed on a variety of foundation systems and in various conditions.

Systems

Subsea Manifold: Remote Control System

The Subsea Manifold is the remote control unit for the Subhub. It is designed to be installed on the seabed and then raised easily onto the deck of the support vessel to take control of the Subhub and quickly connect all the systems to retrieve the Subhub from the seabed.

The Subsea Manifold has been design to be easily deployed and retrieved from the seabed where it lies most of its life in service. It enables all the ballast and data systems to be connected directly into the Subhub and hence allows the support vessel to deploy or retrieve the Subhub remote.

The dyneema tether which is super strong holds the Subhub in position no matter what the wave and tidal conditions. Since the Subhub handles the extreme and dominant forces from waves i.e. heave or vertical forces, it is neutrally buoyant so the tether loads are relatively low because it is free to move in the vertical direction. This makes the Subhub a more robust method of installation and insensitive to wave loading during installation.

Seawater Ballast System

The Subhub’s ballast system replaces the need for large heavy lift support vessels to install and retrieve tidal turbines.

Subhub, elegantly, uses the simple principle of buoyancy to replace large crane vessels that are currently used to install tidal turbines, their foundation structures and ballast blocks.

Subhub, the tidal turbines, the ballast blocks, PTO electrical and transmission equipment, can all be easily installed and recovered as one fully integrated package involving a single offshore operation using a simple barge platform, air compressor and generator which are commonly available at low day rates along with tugs typically £2,000/day to £5,000/day.

Any questions?

We would love to hear from you.

Please don't hesitate to contact us if you have any questions about projects, our technology, or opportunities to work with us.

It has never been more important to make changes to our enrgy supply.

Our technology is ready to make a difference in the supply of sustainable renewable energy.

Contact Details:

11 Castle St, Edinburgh EH2 3AH, UK

+44 (0) 131 202 0362

+44 (0) 778 000 6602